Shopping cart

Newsletter

Sign Up to get updates & news about us . Get Latest Deals from Walker's Inbox to our mail address.

Phone Number:

+91 76027 13555Sign Up to get updates & news about us . Get Latest Deals from Walker's Inbox to our mail address.

Phone Number:

+91 76027 13555

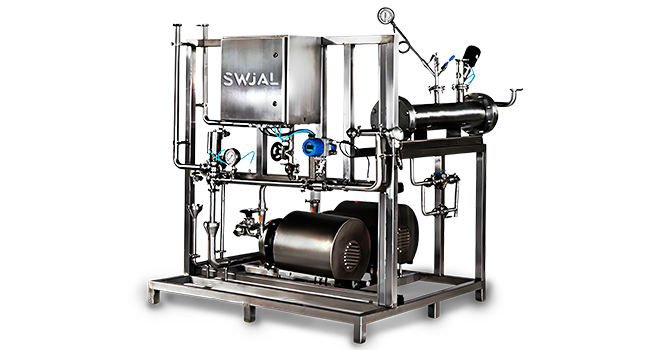

With a deep understanding of pharmaceutical processes, we offer comprehensive WFI solutions tailored to specific client needs. Water for Injection (WFI) systems incorporate advanced technologies and robust construction to deliver reliable and consistent WFI production.

This ensures contamination-free manufacturing processes and maintains the purity and effectiveness of injectable drugs and implantable devices. It helps to prevent contamination throughout the manufacturing process, safeguarding the purity and effectiveness of injectable drugs and implantable devices.

Water for Injection are highly sterile they requires specialized storage and distribution systems to maintain its purity and sterility. SWJAL designs systems that adhere to stringent pharmaceutical standards. Our solutions include insulated storage tanks, circulation pumps, and advanced filtration to prevent contamination. Continuous monitoring and sanitization protocols ensure WFI quality throughout the distribution network.

By adhering to stringent design and operational standards, pharmaceutical water storage & distribution systems guarantee the uninterrupted supply of Water for Injection essential for pharmaceutical manufacturing.

Pharmaceutical water storage and distribution systems ensure a continuous supply of high-purity water to points of use. They typically involve storage tanks, circulation pumps, and distribution pipelines. Water is stored in tanks to compensate for fluctuations in demand and maintain pressure. Circulation pumps ensure constant water movement, preventing stagnation and microbial growth.

Benefits of Water Storage and Distribution Systems