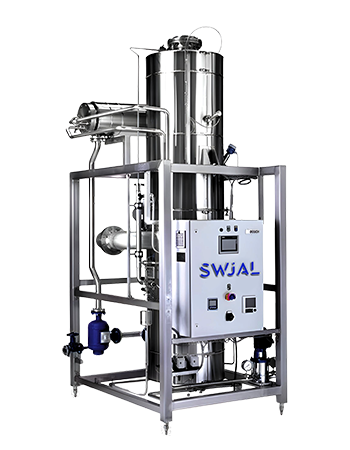

Swjal is leading Pure / Clean Steam Generation System manufacturer in Mumbai, India. Pure steam generation systems, also known as clean steam generation systems, are specialized setups that produce steam of exceptionally high purity. These systems produce steam that is free from impurities and contaminants, making it ideal for sterilization and cleaning processes (CIP/SIP) because it minimizes the risk of contamination in sensitive products in industries like pharmaceuticals, biotechnology, food processing, and even water treatment industries.

Swjals Clean Steam Generation system meet the USP and EU Ph standards for WFI, which specify endotoxins level should be below 0.25 Eu/ml. to achieve this high level of purity, Swjals PSG systems typically employ multiple stages. Pre-treatment removes impurities from the feed water, an evaporation process transforms the water into steam, and superheating eliminates any remaining moisture.

Pure steam generation systems produce steam that meets stringent quality standards, ensuring the elimination of microorganisms and endotoxins. These systems are crucial for sterilization processes (CIP/SIP) and maintaining product integrity.

To meet stringent pharmaceutical standards like USP and EU Ph, pure steam systems incorporate:

Pure steam systems surpasses tests for non-condensable gases, degree of superheat, and saturation with there quality build and design. Additionally, features like electro-polishing of components where pure steam is generated further minimize contamination risks.